About KOCH automation

This is good because we are looking for new employees.

For many years, leading machine and plant manufacturers, as well as power companies, have relied on our know-how for the development and realization of complete electrical systems and automation solutions. In order to guarantee the customer maximum quality, not only do we rely on the security of proven technologies, but also on investing in market-leading systems.

Working with you is a long-term partnership that starts with the task but does not end with the finished solution. After the end of the project, we will continue to assist you with advice and support.

Quality

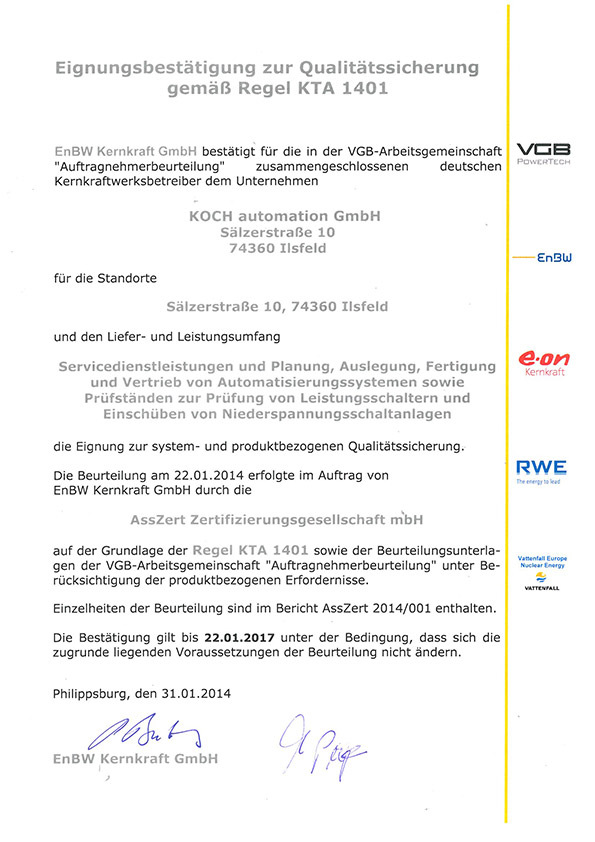

The sustainable quality of your project is our maxim. Our quality management, certified according to DIN EN ISO 9001 and KTA 1401 standards, guarantees you a sustainable project work at the highest level.

Strengths

From conception to commissioning, you get everything with us from a single source. Lean structures allow for maximum flexibility, as well as efficient project handling.

Goals

Our main goal is that you are satisfied in the long term. Therefore, we guarantee the highest product quality, a partnership-based relationship and a fast and goal-oriented project management.

Safety

We ensure a high degree of safety by means of continuous training, as well as strict adherence to all applicable laws, standards and safety regulations.

Where we come from and where we are today

KOCH’s focus was not always on process automation. At the beginning the company, which was founded by Kuno Koch in the 1960s, was focused on the design and manufacturing of press controls and sheet metal processing plants.

Only in course of time did our know-how and technology extend to the entire range of process automation. Kuno Koch quickly led the company to success and made a lasting impact on tradition and quality.

This year the groundbreaking ceremony for the new building took place in the Böllinger Höfen in Heilbronn.

The year 1994 was a year of innovations and developments:

The KOCH team further expanded the field of testing facilities for nuclear power plants and standardized the individual production of test stands. As a result, the test stand software KPS2000 was developed for low-voltage feeders and circuit breakers.

After the introduction of the quality management system according to ISO 9001, the company received certification in accordance with KTA1401 (Safety Engineering Rules of the Nuclear Technology Committee) the same year.

In 2003, Kuno Koch placed the management in the hands of long-term employees. They continue to uphold the tradition that all shareholders are actively involved in the company and are personally involved in all areas.

What was long in preparation was finally realized. In March 2012, the entire team moved into the current KOCH building in Ilsfeld. Modern office spaces have made our day-to-day work even more enjoyable, switch cabinets and switchgear can be produced in the ample space in our production hall.

This year we can look back on 50 years of improvements, changes and innovations and are proud to be a part of this long journey and a sustainable company. Over the next 50 years, our more than 20 qualified employees will form a highly flexible company which, thanks to the experience of each individual, covers all areas of process automation.