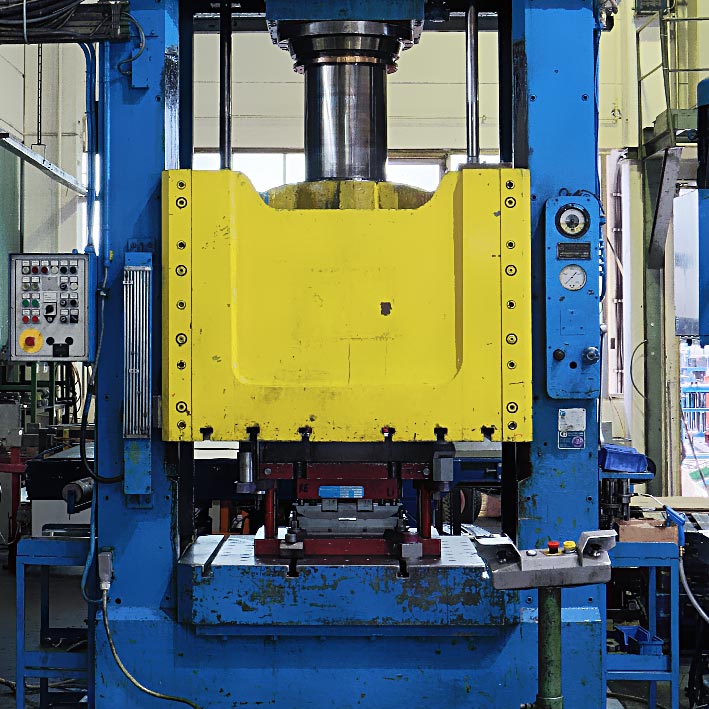

Retrofitting: Hydraulic presses

We can achieve this by modernizing your hydraulic presses

Retrofitting with energy-efficient electric drives

Retrofitting electronic camshaft controllers

Automated adjustable axes

Tool magazine allows for much shorter changeover times

Bring safety systems up-to-date

Avoid procurement issues for discontinued replacement parts

Good to know:

What are hydraulic presses?

Hydraulic presses work according to the hydrostatic principle. Hydraulic pumps driven by an electric motor generate pressure, which in turn is transmitted to the ram via cylinders. Because of this property, they are particularly suitable for drawing operations, since the ram’s position does not matter to utilize maximum force. Hydraulic presses, however, are not only used for cutting, but also in Testing, Die-Spotting and Try-Out presses, which is why they can be found in almost every area of metal forming.

REFERENCES

We modernize hydraulic presses of different manufacturers from all over the world.

Here is a small selection of our references:

Dieffenbacher

Lasco

ZDAS

SMG

AP&T