Retrofitting: Mechanical presses

We can achieve this by modernizing your mechanical presses

Retrofitting of the speed for controlled drives for variable stroke rates

Replacement of mechanical speed adjustments (e.g. PIV transmission)

Conversion from DC motors to maintenance-free AC motors

Energy savings through energy-efficient drives and regenerative power supply

Automatic stroke adjustment

Retrofitting electronic camshaft controllers

Tool magazine allows for much shorter changeover times

Bring safety systems up-to-date

Avoid procurement issues for discontinued replacement parts

Good to know:

What are mechanical presses respectively eccentric presses?

Mechanical presses, or eccentric presses, are electric motor driven, stroke-controlled Press types that are used for cutting and punching, and stamping and bending work with small press strokes. Via a belt drive, a flywheel is driven, which is connected via a coupling to the eccentric shaft. The force on the ram (driver) is converted into a linear movement by the connecting rod mounted on the eccentric shaft.

References

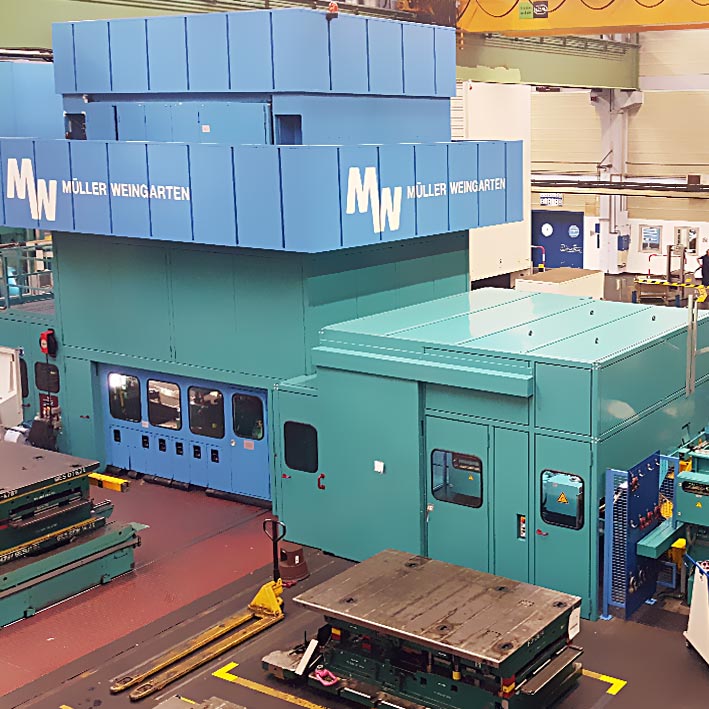

We modernize mechanical presses from various manufacturers from all over the world.

Here is a small selection of our references:

Heilbronn Mechanical Engineering

Haulick + Roos

AIDA

Bliss

Müller Weingarten