Retrofitting of metal packaging systems

We can achieve this by modernizing your

metal packaging plants:

Long-term process security

Conversion from DC motors to maintenance-free AC motors

Use of highly dynamic, energy-efficient drive systems

Tool magazine allows much shorter changeover times

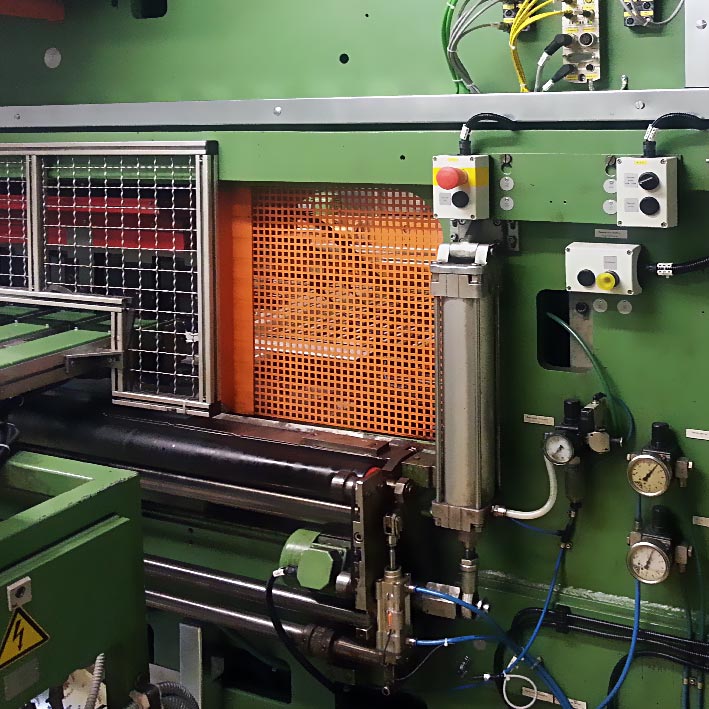

Bring safety systems up-to-date

Avoid procurement issues for discontinued replacement parts

We have modernized the systems of the following manufacturers:

Naroska

Alfons Haar Mechanical Engineering

Dimeco

HEILBRONN

Mailänder

Good to know:

What is Metal Packaging?

In the packaging industry, high-quality and efficient manufacturing solutions are required to ensure high output performance and the best product quality at the same time. Here CNC Sheet Feed Presses for the production of cups and lids (Shells and Ends) and Easy Open Ends presses for the production of tear-off lids (EOE) are used.

In this area of metal packaging we modernize complete production lines with dry kilns, rubber coating, rotary printing presses or painting facilities.

References

We modernize metal packaging systems of different manufacturers from all over the world.

Here is a small selection of our references: